Dear clients! Experts with many years of experience will help you find the perfect solution for your needs. We also offer free consultations on the mounting of insulation materials.

Cotton is a natural ecological material, our plates are made of textile cotton. Does not contain adhesives, formaldehydes, other volatile compounds. The plates are stable. Its chemical composition does not change with increasing or decreasing ambient temperature and humidity.

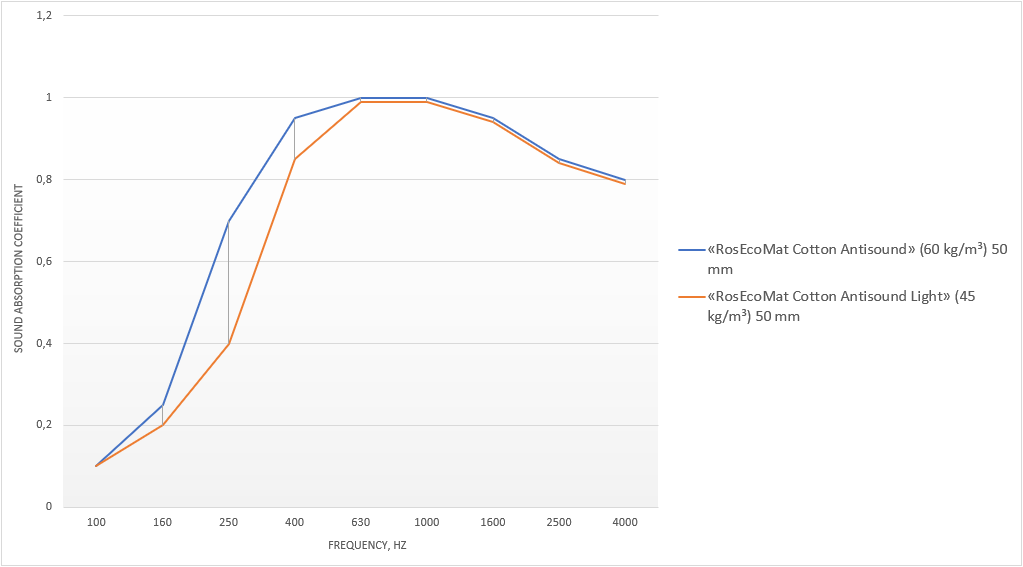

Cotton plates perfectly dampen sound vibrations. The average sound absorption coefficient of the cotton panels is 0.82 in the range 100 Hz to 4 kHz. Provides air noise reduction from 43 dB to 62 dB.

Cotton absorbs shock and structural vibration slightly worse due to its relatively low weight.

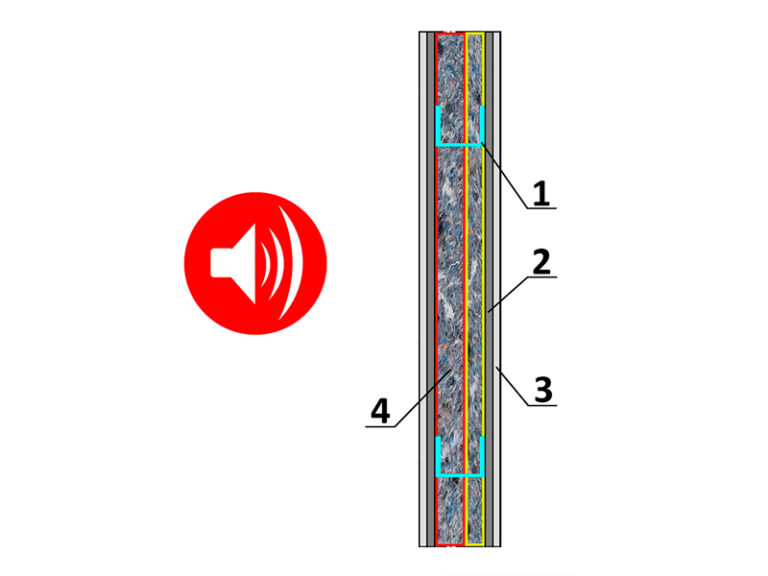

To improve the sound absorption effect of the sound wave spectrum in the private sector, we recommend alternating our cotton panels with different densities. Thickness 25 or 50 mm.

In our assortment there are also plates made of polyester fiber «RosEcoMat Polyef Antisound», hemp fiber «RosEcoMat Kenaf Antisound» as an intermediate layer in frame sheathing.

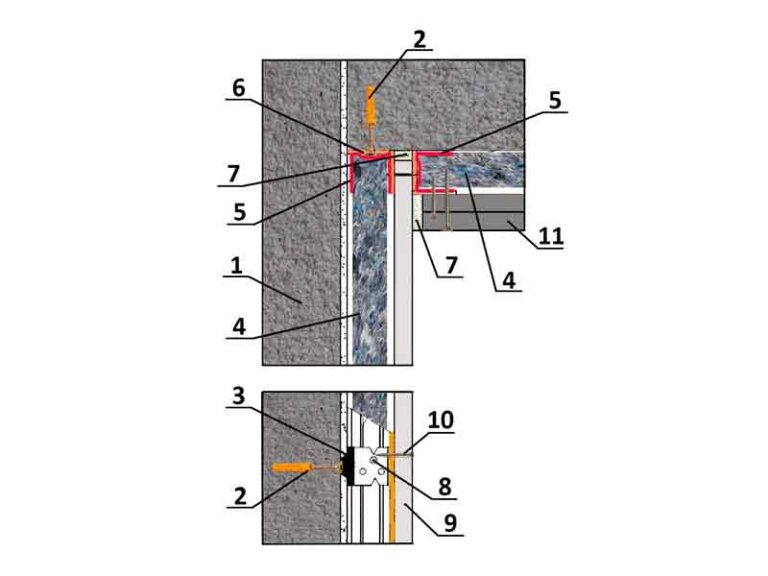

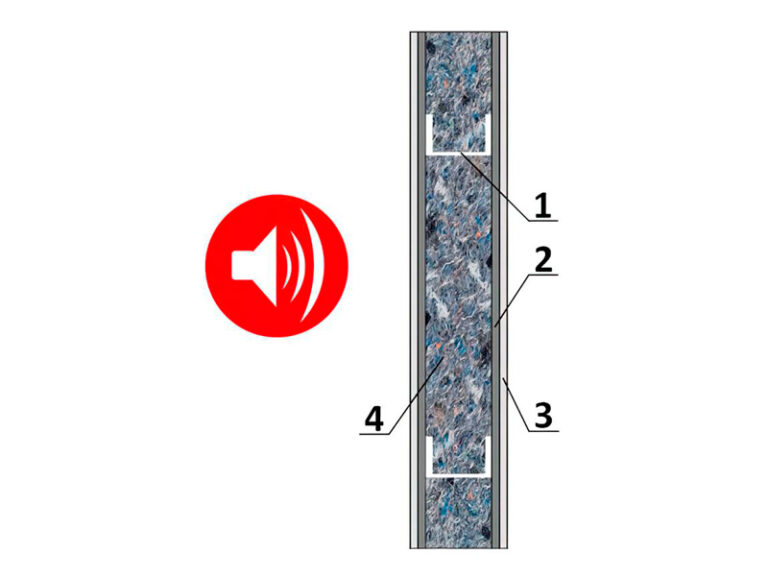

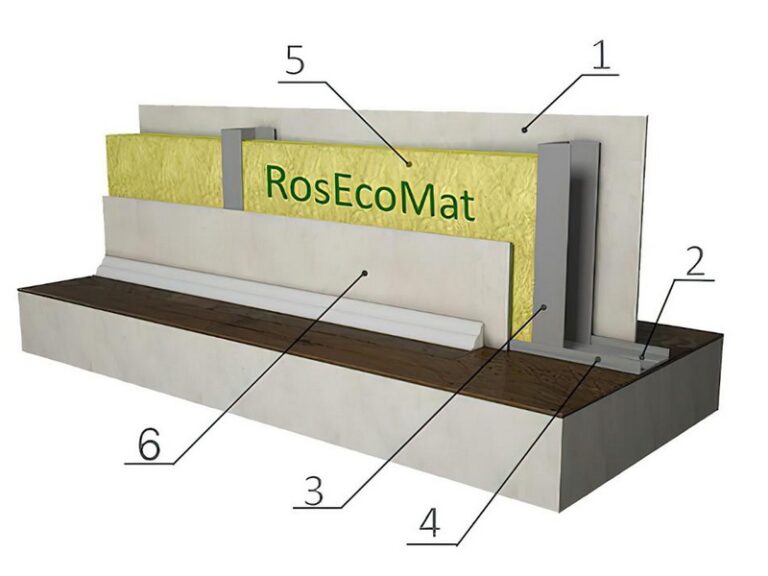

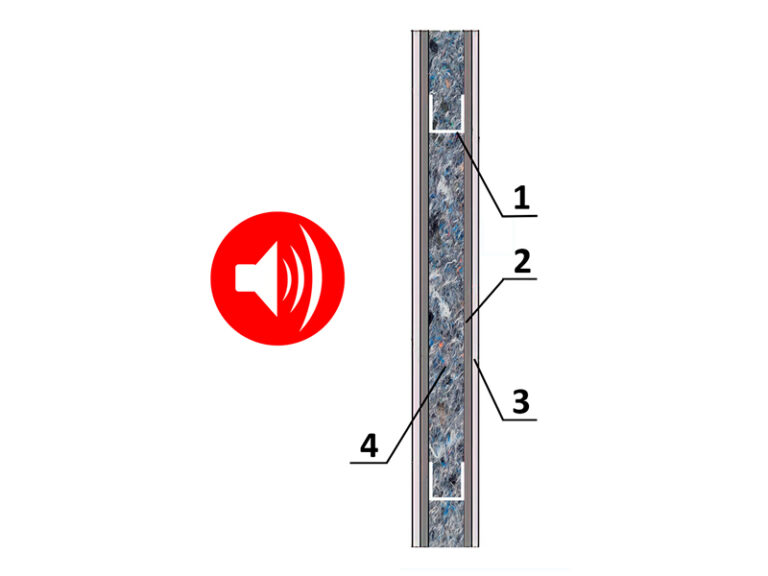

The plates have increased elasticity and do not shrink when used in frame structures for their entire service life. The plates are mounted off and in most cases do not require additional fasteners. For the device of the frame are used wooden slats (bars) or metal profile. Use sturdy boards such as GKL, DSP, fibreboard, etc. to sheath the frame. For interior work plywood and OSB are not desirable.

Advantages for soundproof constructions:

- Optimum density for sound absorption

- High mechanical strength

- Absence of deformation throughout the service life

- Vapour permeability

- Hypoallergenic

Application in sound insulation constructions:

- floors on logs

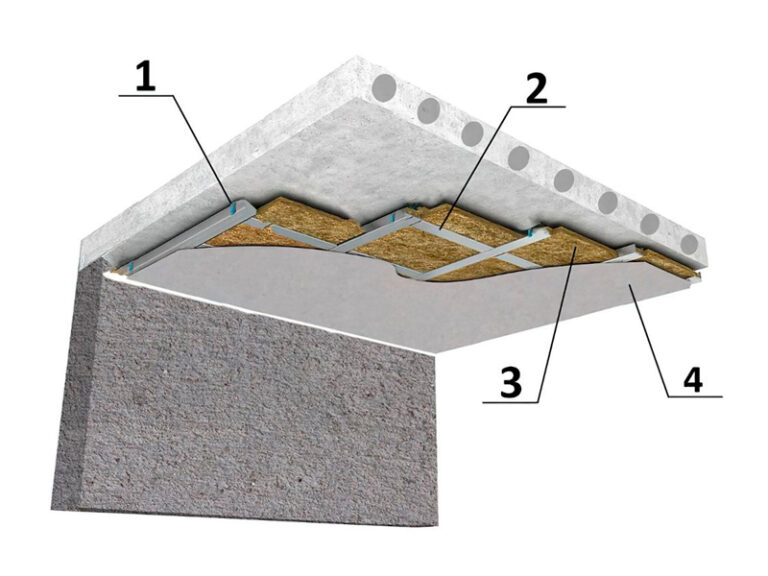

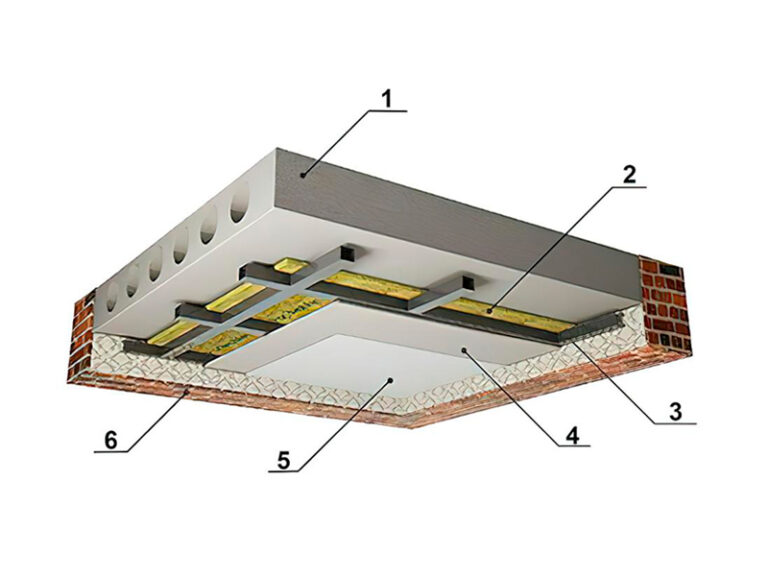

- lowered ceilings

- framework shares

- bearing walls (additional sound insulation)

Suitable for children and medical institutions. The plates are packed in polyethylene film.

Size and packaging

| Length(mm) | Width(mm) | Thickness(mm) | Packing area(m2) | Packing volume(m3) | Panels in packaging |

| 1000 | 600 | 25 | 6 | 0,15 | 10 |

| 1000 | 600 | 50 | 3 | 0,15 | 5 |

| 1000 | 600 | 100 | 1,2 | 0,12 | 2 |