Dear clients! Experts with many years of experience will help you find the perfect solution for your needs. We also offer free consultations on the mounting of insulation materials.

Applications of «RosEcoMat Woolen Ribbon»:

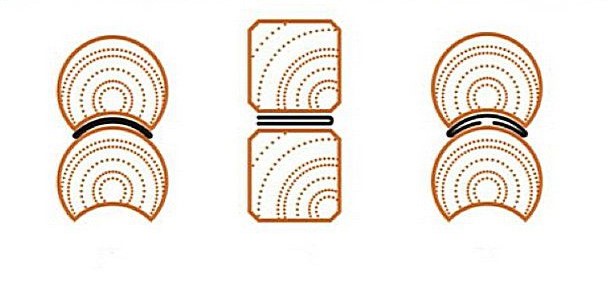

- Sealing joints in log and timber houses.

- Insulating corner joints and tenon connections.

- Providing additional thermal and acoustic insulation in wooden structures.

- Use in the restoration of old log houses.

Differences compared to other joint insulation materials:

- Compared to jute: wool is softer, more elastic, does not crumble, and does not cause wood decay; unlike coarse jute, it does not draw moisture into the joint.

- Compared to flax felt: wool has «living elasticity» and does not permanently compress over time, whereas flax compacts and may create thermal bridges.

- Compared to synthetic materials: a natural product that «breathes» with the wood and emits no harmful substances.

- Compared to moss or tow: a modern, more hygienic solution that requires no extra preparation and does not attract insects.

Advantages of «RosEcoMat Woolen Ribbon»:

- Natural and eco-friendly — 100% sheep’s wool with no chemical additives.

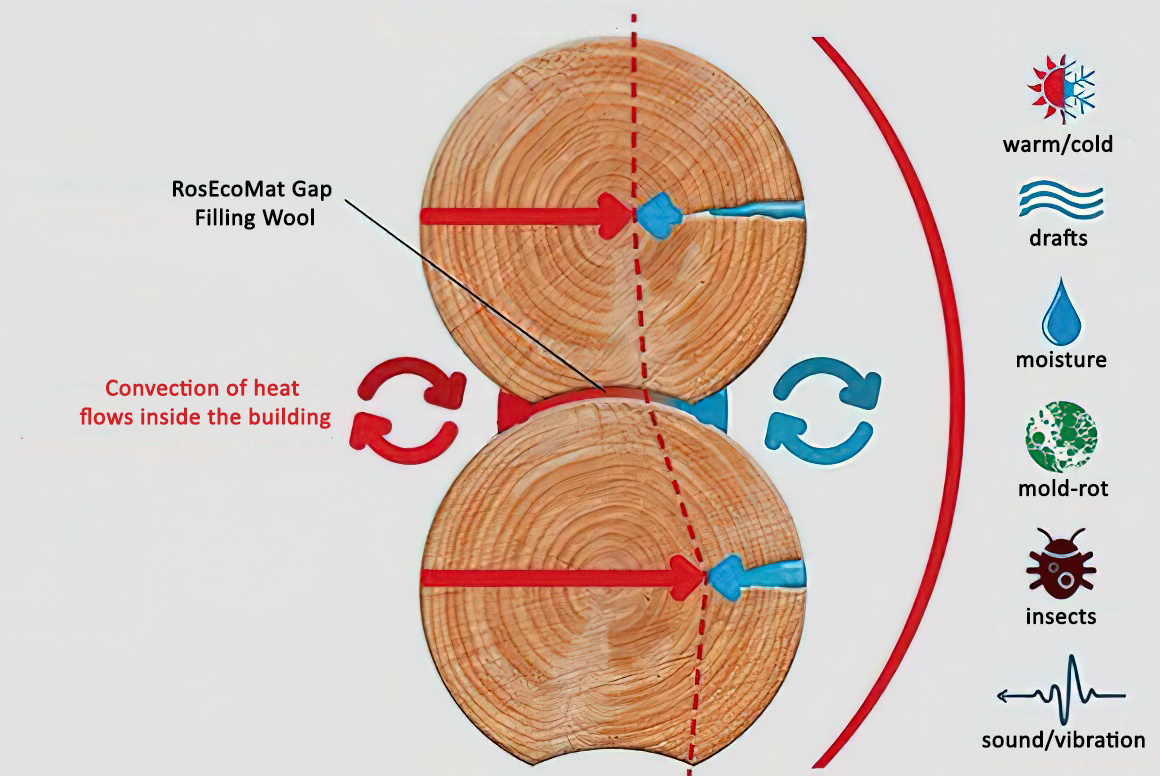

- Elastic and durable — maintains its form and compensates for wood shrinkage.

- Thermal insulation — high heat-retention capacity thanks to natural keratin fibers (fine fiber thickness 23 μm).

- Hygroscopic — regulates moisture in the joint and prevents wood decay.

- Biologically resistant — treated wool is unattractive to moths and insects.

- Easy to install — convenient ribbons can be quickly placed into joints.

- Wood compatibility — the same «breathable» structure, preventing condensation and mold formation.

- Fire-resistant — wool requires 25,2% oxygen to ignite, while the air contains only about 21%. Its ignition temperature is 580 °C.

- Hypoallergenic — sheep’s wool is skin-friendly.

- Neutralizes unpleasant odors.

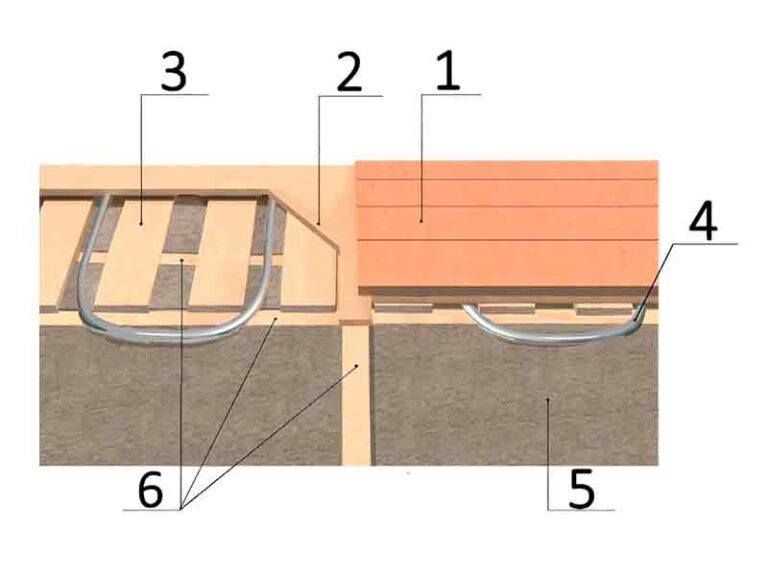

The ribbon width is chosen according to the size of the log, beam, or profile groove designed specifically for gap insulation. If necessary, two or more layers can be applied for a tighter fit, depending on the geometry of the logs or beams.

Installation is straightforward — the insulation ribbon is fastened to the wood with a stapler.